The electronic content in automotive is exploding, the market for automotive electronics systems is expected to grow from $170 billion in 2011 to $266 billion by 2016 (Strategy Analytics). When you seat in a brand new car, you immediately see the difference with a ten or even five years old vehicle, as you can exercise MP3 music readers, GPS or smartphone-like touch screen, all of these functions called infotainment. But there is a segment representing an even strongly growing market, namely automotive sensing system market. When driving a car, you certainly activate sensor based functions. Sensors are by nature analog functions, at the edge of the real world, even if the processing will be supported by digital processor or MCU later in the data flow, and a sensor will need to be calibrated. As we can see below, this calibration will have to be done multiple times during the sensor life cycle, and the related data safely stored. Then, the ideal location is within a Non Volatile Memory (NVM). In fact you need a small memory size, from 128 bits to 2K bits, and to optimize the system real estate, power consumption and overall cost, using a NVM IP instance integrated into the main IC is the best option.

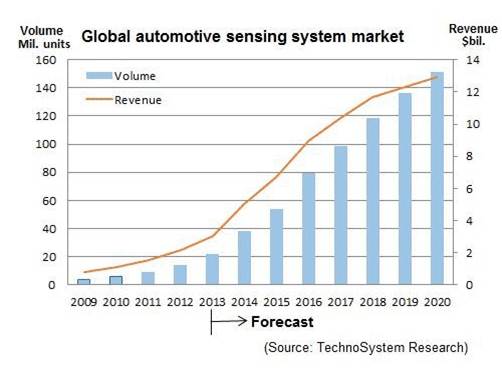

This automotive sensing system market is attractive, due to the strong growth rate expected for the next five years, but this market is also very demanding in term of quality standard, data retention, test coverage… and cost. According with John Koeter, vice president of marketing for IP and prototyping at Synopsys, “Designers developing automotive ICs increasingly expect NVM IP providers to support the Grade 0 temperature range (-40 to +150C) and AEC-Q100 standards while reducing IP area and cutting test times.”

Synopsys DesignWare AEON Trim NVM IP is available in standard 180-nanometer (nm) 5V CMOS and Bipolar CMOS DMOS (BCD) processes without a need for additional masks or process steps. In addition, faster programming times reduce NVM test times by 3X compared to alternative NVM solutions, enabling designers to reduce production test times and minimize test costs for automotive and industrial ICs.

I recommend you to listen to this webinar: Designing with Non-Volatile Memory for High-Volume Automotive ICs, as it will give you the opportunity to go very deep inside the NVM technology and better understand the relation between data retention requirements and test strategy, as well as to understand how stringent is the automotive AEC-Q100 quality standard. There is also a good white paper available on this topic: Developing High-Reliability Reprogrammable NVM IP for Automotive Applications.

Just take a look at the automotive sensing system market evolution, the growth rate is impressive: from 20 million units in 2013 up to 150 million in 2020!

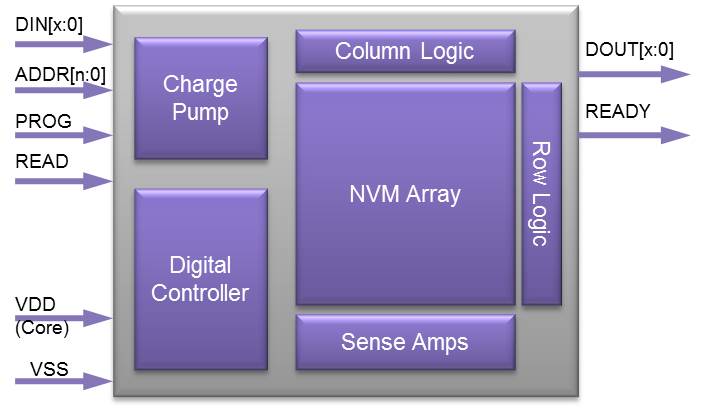

Coming back to DesignWare NVM IP cell, it’s important to notice that the architecture is not based on One Time Programmable (OTP) or even a few-time programmable (FTP) cell, but really a Multiple time programmable NVM offering endurance up to 10k cycles for 128 bits to 2k bits instances and over 15 years of data retention in automotive applications. Such a VNM IP is to be integrated into a chip targeting 180-nanometer (nm) 5V CMOS and Bipolar CMOS DMOS (BCD) processes and no mask adder, it’s important to notice that the IP operates from a single core supply only (1.8V), thanks to the integrated charge pump. For the chip designer, this NVM IP can be integrated as a black box (no need to be a NVM expert), offering 3X improvement in NVM test time due to faster programming and 75% improvement in area, allowing keeping the overall cost as low as required by the automotive market.

Did you know that more than 500 million ICs with DesignWare NVM IP ship each year? The company is committed to delivering high quality and high reliability IP through extensive test and qualification methodology developed over more than 10 years in NVM, attacking now the sensing system market with this AEON Trim NVM IP.

From Eric Esteve from IPNEST

More Articles by Eric Esteve…..

Share this post via:

Comments

0 Replies to “How to Trim Automotive Sensor?”

You must register or log in to view/post comments.